Fluid Bed Batch Dryers & Coolers

For pilot plant testing and laboratory applications

Kason Corporation's circular vibratory fluid bed batch dryers, coolers, and moisturizers provide cost-effective processing solutions. The innovative designs take up a smaller space without compromising processing performance. Learn about the benefits of a circular vibratory fluid bed design compared to rectangular fluid bed units in our recent blog post.

Our VIBRO-BED circular vibratory fluid bed batch dryers, coolers, and moisturizers are ideal for pilot plant testing and laboratory applications.

Looking for aftermarket parts? Click Here

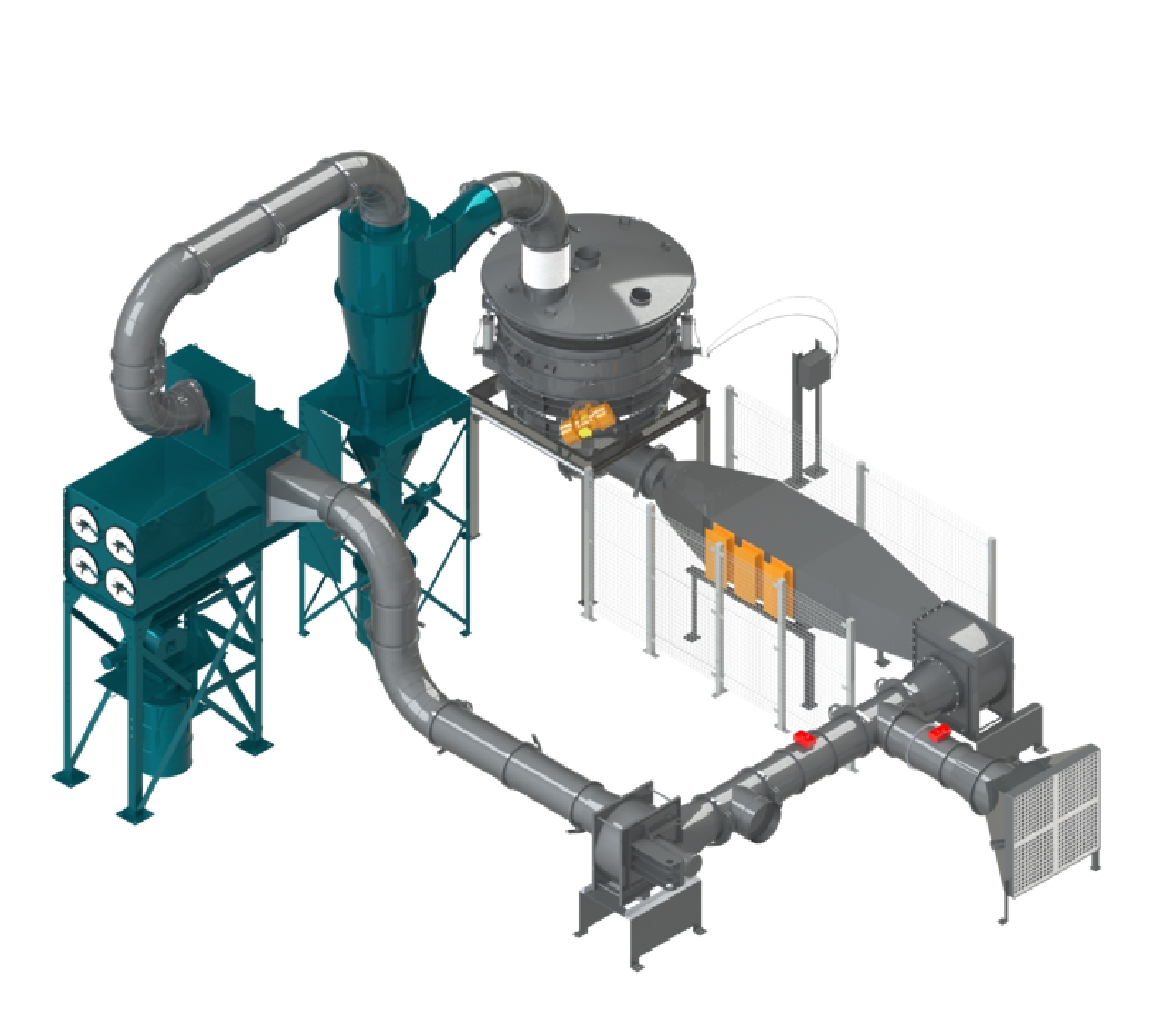

Vibro-Bed Energy Recovery System

Recycles Exhaust Air for Up to 50% Energy Savings

Save even more on energy, lower emissions and improve air quality with a fluid bed energy recovery system from Kason.

- Recirculate Heated Air for Up to 50% Energy Savings

- Enhance Environmental Air Quality

- Reduce Unwanted Odors & Emissions

- 12 Month Payback Period

Perfect for new installs, retrofits and competing drying systems. Ideal for a wide variety of drying applications including:

- Drying Temperatures Exceeding 150°F (66°C)

- Large Particles that Don’t Release Moisture Easily

- Material with Bound Moisture Content

Kason VIBRO-BED Fluid Bed Batch Dryers, Coolers, and Agglomerators

View ConfigurationsWe offer three models of VIBRO-BED fluid bed batch dryers, coolers, and agglomerators, which can be customized to your specific processing requirements. Standard contact surfaces are in 304 stainless steel but are available for manufacture in 316 stainless steel or higher grades as required. Optional features include explosion-proof electricals and clean-in-place (CIP) spray heads.

Each model features a choice of fluid bed air distributor, plus an adjustable weir to control the bed depth.

How our Fluid Bed Processor works

THE RIGHT CONFIGURATIONS FOR YOUR NEEDSDrying, Cooling and Agglomerating Equipment Guide

What type of fluid bed is best for your application? Download our free guide to learn everything you need to know.

New! Fluid Bed Exhaust Recycling

This partial loop drying system can be added onto new installs or retrofitted on Kason or competing fluid bed drying systems to recycle a portion of the heated air used by the fluid bed. A programmable logic controller opens and closes a series of backdraft dampers to force previously heated air back in the dryer for up to 50% energy savings. Other benefits include: lower fossil fuel and particulate emissions, reduction in unwanted odors and improved air quality.

Laboratory Batch Dryer

This drying system is ideal for pilot-plant and laboratory applications. Available in 304 stainless steel, the batch dryer can be constructed with fluid bed processors ranging from 18 inches (460mm) to 24 inches (610mm) in diameter. It features a surge bin, rotary valve, heater, blower, and controls on a caster-mounted frame. The Laboratory Batch Dryer can also be configured for continuous operation.

Medium Capacity Fluid Bed Processor

Constructed in 304 stainless steel, this fluid bed dryer reduces the moisture content. Its circular design fulfills a range of medium volume production applications not satisfied by rectangular systems and does so with high operating efficiency at low capital cost.

High-Temperature Batch Dryer

This compact circular vibratory fluid bed processing system dries small batches of bulk solid materials at high temperatures, up to 600 degrees Fahrenheit (315 degrees Celsius). The 18-inch fluid bed processor is ideal for small-volume production and laboratory/pilot plant testing. It features a heater, blower, cyclone separator, and controls on a caster-mounted frame.

Product Benefits

Some of the main benefits of our batch dryers, coolers, and agglomerators include:

Strong, light, and cost-effective

High-torque motor drive for optimal vibratory motion

Quick-disconnect clamps and minimal interior seams enable easy cleaning and maintenance

Optional construction to 3-A, FDA, and BISCC standards

Vibratory Fluid Bed Models

Contact UsWe also offer a range of circular vibratory fluid bed models that can handle both batch and continuous drying, cooling, and agglomerating, including:

- Fluid bed processors with air-lift devices

- Fluid bed dryer-screener systems

- Circular fluid bed systems

- Fluid bed agglomerators

Related Resources

Find Out More

With over 50 years of manufacturing excellence, Kason Corporation has an expansive range of screening and separating solutions - from standard, off-the-shelf options to highly customized built-to-spec equipment. Our products are designed to the highest possible standards so that they consistently exceed the expectations of our customers.

We support businesses and industries across the globe through our offices and an extensive global network of representatives. Contact one of our friendly professionals today to see how we can help your business.

Ask Us a Question

Contact us with any inquiries and we will make sure to contact you soon