Powder Processing Equipment

Our high-performance powder processing equipment ensures the high-quality and reliable processing of all kinds of powders. For over 50 years, Kason Corporation has provided powder processing solutions for food, chemical, and pharmaceutical businesses worldwide.

Kason’s powder processing equipment is available in a host of standard and custom-engineered models that can be designed to meet your specific requirements for sifting, screening, mixing, blending, drying, and more!

Powder Processing Equipment Applications

Kason Corporation is a global leader in manufacturing high-performance powder processing equipment. All models can be constructed in sanitary 304 and 316 stainless steel, and we also offer a range of exotic alloys and finishes compliant with USDA, FDA, BISCC, 3-A, and other stringent US and international sanitary and safety standards.

Powder Screening Equipment: Our VIBROSCREEN circular vibratory screeners can sift, de-dust, and classify a wide range of powders, eliminating any unwanted solids and ensuring consistent and reliable processing. We can supply our screeners in a wide range of single or multi-deck configurations, for batch or continuous processing.

Metal Powder Reclaiming Equipment: The latest in Kason's VIBROSCREEN circular vibratory sifters, the 3D ReKlaimer Additive Recovery System improves Additive Manufacturing (AM) powder reclamation processes. The unit screens and reclaims powders used in 3D printing technologies like selective laser sintering (SLS), fused deposition modeling (FDM), and stereo-lithography (SLA).

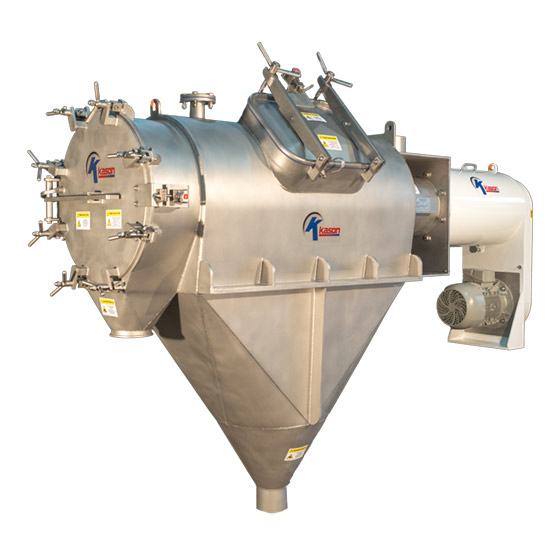

Powder Sifting Equipment: Kason’s CENTRI-SIFTER centrifugal sifting and separating equipment can sift, scalp and de-lump virtually any bulk solid. Featuring a dust-free, sanitary operation, our centrifugal separators are available in quick-clean, cantilevered, twin, and other configurations and designs.

Powder Sieving Equipment: We also manufacture CROSS-FLO static scalping sieves for removing oversize particles from dry bulk solids. The economical, zero-energy units are ideal for continuous scalping applications and available in various sizes and configurations.

Powder Size Reduction Equipment: Our lump breakers and cone mills are ideal solutions for de-agglomeration, pre-milling, and coarse grinding applications. ATEX models are available.

Some typical applications of our powder processing equipment include:

- Sieving bulk products

- Batch and continuous powder blending

- Granulation of small powders

- De-agglomeration and de-lumping

- 3D printing and additive manufacturing recycling systems

Related Products

Products for the Powder Processing Industry.

Find Out More

In addition to our powder screening, sifting, and scalping equipment, we supply a wide range of re-placement and aftermarket parts for all makes and models of screening and sifting equipment. We can arrange for expedited shipping for urgent repairs or Just-in-Time delivery for scheduled preventative maintenance.

Contact one of our friendly team members today to learn how our powder processing equipment can save your business time and money.

Ask Us a Question

Contact us with any inquiries and we will make sure to contact you soon

.png)