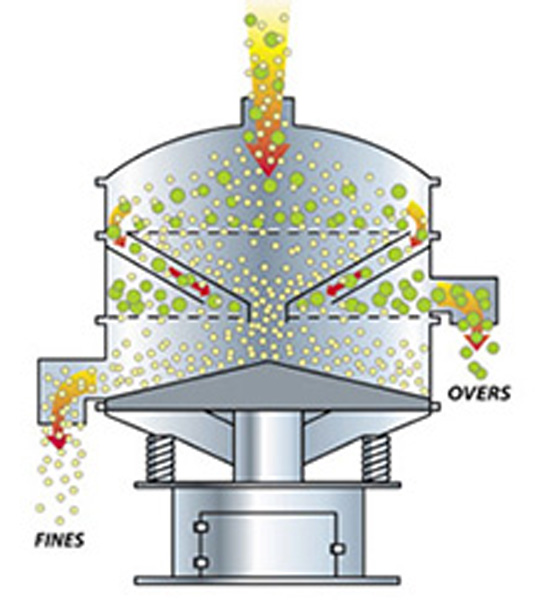

Two-Stage 'RC' Circular Vibratory Screener

This "RC" VIBROSCREEN® "Two-Stage" circular vibratory screener reportedly offers 60 to 80 percent higher capacities than conventional screeners of the same diameter.

Attributes

- Designs for Sanitary Applications

- "Air-Lift" Quick Screen Change System

- "Clamshell Lid" Quick Screen Change System

- Clean-In-Place (CIP) Design

- Pharmaceutical Specifications

- Gap-Free Design

- E-Z Forceª Weight Adjustment System

- Ball Tray Anti-Blinding Device

- Kleen Screen Anti-Blinding Device

- Ultrasonic Anti-Blinding Device for fine powders

- Auto-Lube Automatic Lubrication System for gyratory motors

- Wiper Blade Assembly

- Four-Finger Flex Wiper Anti-Blinding Device

- Bag Dump

- Dust Collector

- See-Through Dust Cover

- High Capacity "KASCADE" Internal Recycle Screening Decks

Need help? Contact Us Here

Product Information

The two-stage design features an upper screen deck having a 360¡ annular gap at the screen's periphery. This deck is fed with more material than it can efficiently screen, with two results: 1) On-size material falling through the upper screen is funneled through a hole in the center of the lower screen to the machine's discharge outlet and 2) The overflow of on-size material plus all oversize material cascade over the screen's periphery, onto a second screen of equal mesh that scalps the balance of material in normal fashion.

The two-stage machine boosts capacity without increasing floor space, and costs 20 to 30 percent less than conventional screeners having larger diameters and equivalent capacities.

The two-stage screening hardware can be installed in new circular vibratory separators or retrofitted on site in existing circular screeners. Two-stage machines are offered in diameters from 40 to 100 inches (1016 mm to 2450 mm) to scalp up to 70 tons of free-flowing bulk material per hour. Available to 3-A, USDA, FDA, BISSC and other sanitary standards, the units can be disassembled rapidly for thorough wash-down.

A range of accessories is available including clean-in-place spray heads, anti-blinding devices, quick-release clamshell lids for rapid screen changes, and an automatic long-term lubrication system for gyratory motor bearings.

Ask Us a Question

Contact us with any inquiries and we will make sure to contact you soon