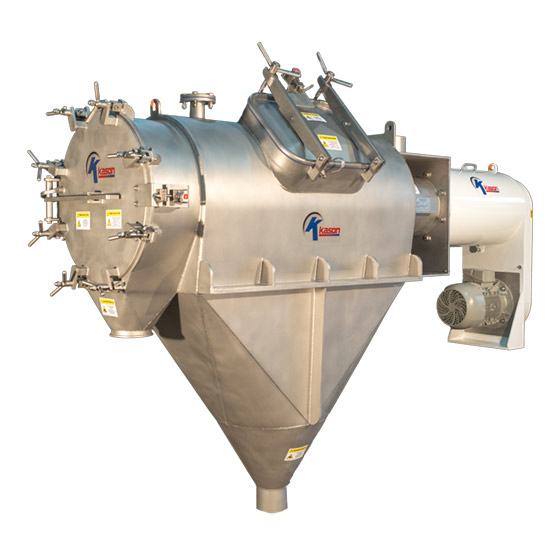

Centrifugal Sifters & Separators

Screening powders, granular materials, and continuous scalping of dry or moist materials with Kason's CENTRI-SIFTER

For over 50 years, Kason Corporation has been supplying versatile, high-capacity, compact, and economical centrifugal sifters and separators to businesses for industrial, chemical, food and beverage, distillery waste removal, and pharmaceutical applications.

The innovative design of our centrifugal sifters and centrifugal separators make them ideal for a wide range of applications such as screening powders and granular materials, continuous scalping of dry or moist materials, separating liquids and solids.

Looking for aftermarket parts? Click Here

Kason CENTRI-SIFTER Centrifugal Sifters & Separators

Looking for replacement parts? Click Here

Our extensive range of centrifugal sifters and separators can sift, scalp, de-lump, and de-water virtually any bulk solid or slurry. The Kason Centrifugal Sifter is available in many configurations designed to solve specialized problems and continuously deliver high performance.

With a compact design, our range of centrifugal sifters and separators offer an economical option for screening powders or granular materials at the rate you require, on a batch or continuous basis. The main features of our centrifugal sifters include:

- Gravity-fed or in-line pneumatic conveying systems

- Dust-free, sanitary operation

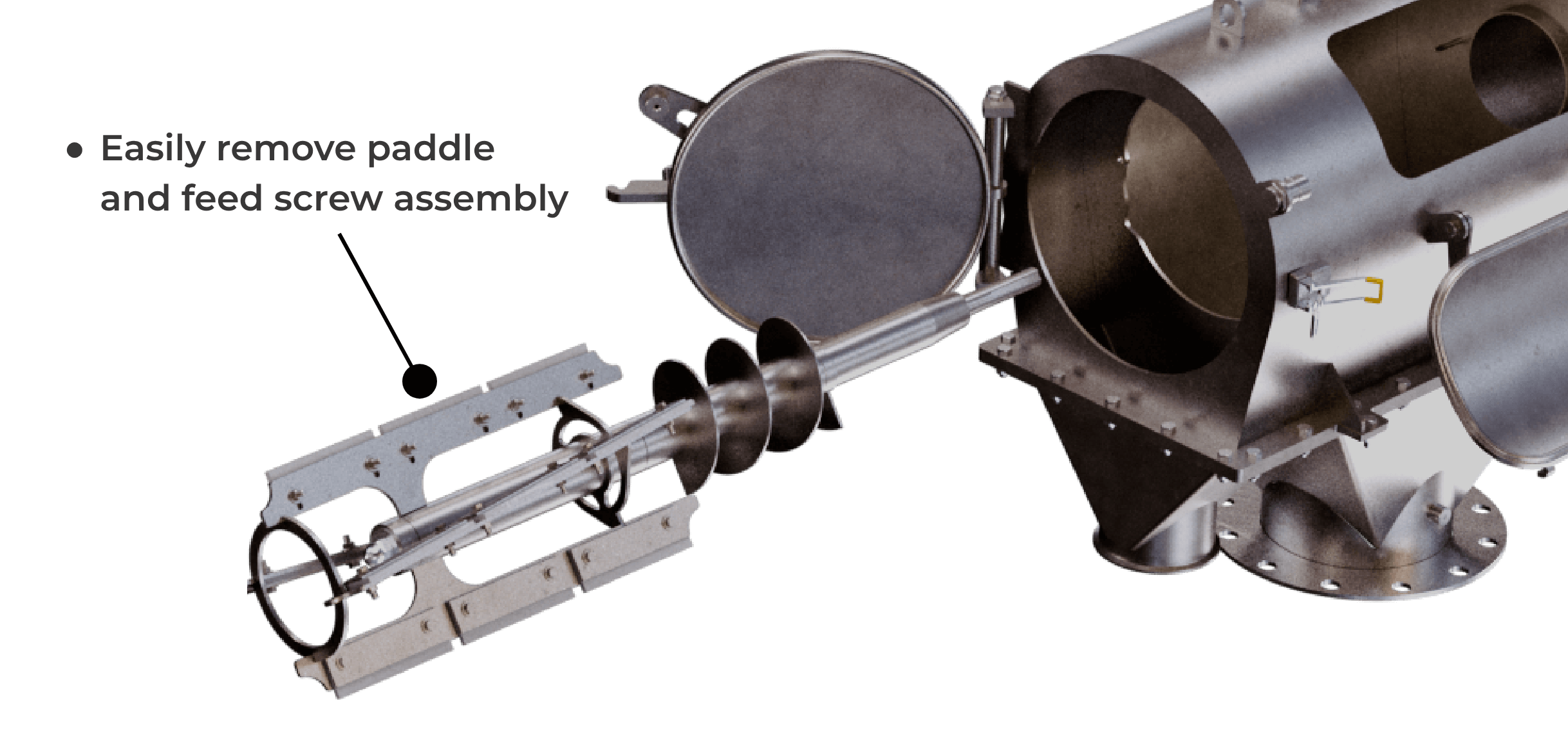

- Easy clean-out

- Quiet, vibration-free action

- Quick screen change

- Rapid sieving action

- Double seal outboard bearings

- Single or twin models

- Heavy-duty construction for batch or continuous operation

All of Kason's Centrifugal Sifters are approved for use by USDA, FDA, BISCC, 3-A, and other US and international safety and sanitary regulations.

The Right Configurations for Your Needs

What type of centrifugal screener is best for your application? Download our free guide to learn everything you need to know.

We understand that different industries and organizations have unique requirements, so we have designed a range of products that can be easily adapted to your needs. We offer gravity-fed and in-line pneumatic models with single or multiple screening decks, one or multiple motors, and a wide range of sizes. Our range of models include:

- Quick-clean centrifugal sifters

- Pneumatic in-line centrifugal sifters

- Bag dump centrifugal sifters

- Sanitary centrifugal sifters

- Centrifugal de-watering separators

The Kason Centrifugal Sifters & Separators are available in a wide range of sizes, available in standard, off-the-shelf designs as well as highly customized configurations built for your business's specific needs.

Shop Our Products Below! Click Here

Typical Capacities

All Kason centrifugal sifters, screeners, & separators are constructed of stainless steel with optional sanitary finishes suitable for pharmaceutical, food, and dairy applications, as well as industrial applications involving frequent screen changes, inspections or runs of multiple materials with no cross-contamination. *Bulk materials listed are a sampling of hundreds of products screened using CENTRI-SIFTER centrifugal sifters. Capacity ranges shown may vary by application.

Food & Dairy

| Material | Typical Capacity |

|---|---|

| COCOA POWDER | 1-70 TPH |

| FISH MEAL | 1-40 TPH |

| FLOUR | 1-60 TPH |

| GROUND COFFEE | 1-30 TPH |

| LACTOSE | 5-300 GPM (20-1850 LPM) |

| MILK POWDER | 1-30 TPH |

| NON-DAIRY CREAMER | 1-50 TPH |

| SPICES | 1-40 TPH |

| STARCH | 1-50 TPH |

| SUGAR | 1-120 TPH |

| TOFU | 5-200 GPM (20-900 LPM) |

| DISTILLERY SPENT GRAIN | 10-150 GPM |

Chemical

| Material | Typical Capacity |

|---|---|

| CALCIUM STEARATE | 1-30TPH |

| EXPANDED SILICA | 0.5-6 TPH |

| HYDRATED ALUMINA | 1-30 TPH |

| IRON OXIDE | 1-40 TPH |

| LATEX | 5-200 GPM (20-900 LPM) |

| PAPER FIBER | 5-400 GPM (20-1800 LPM) |

| PIGMENTS | 1-40 TPH |

| POLYMER BEADS |

1-250 GPM |

| POWDER COATINGS | 1-30 TPH |

| TiO2 SLURRY | 5-250 GPM (20-1150 LPM) |

Mineral

| Material | Typical Capacity |

|---|---|

| CALCIUM CARBONATE | 1-70 TPH |

| EXPANDED PEARLITE | 0.25-7 TPH |

| GYPSUM | 1-90 TPH |

| MICA | 0.25-10 TPH |

Centrifugal Sifters & Screeners

Find Out More

For over 50 years, we have been manufacturing innovative screening, sifting, and separating solutions for various applications. With a global network of offices and representatives, we are here to support your business wherever you are.

The team at Kason Corporation can walk you through the different options available to get the best fit for your business. We also offer an extensive range of replacement screens and parts, as well as free lab testing, to ensure that your equipment delivers the consistent results that your business requires.

Contact one of our friendly professionals today to learn more about our high-performing and cost-effective centrifugal sifting equipment.

Related Resources

Ask Us a Question

Contact us with any inquiries and we will make sure to contact you soon